Addressing the Ongoing Challenge of Sharps Injuries: A Commitment to Workplace Safety

By Sarah Umandap, BS, MS; Kevin McGlinchey, BS, MT (ASCP), CLs (CG); and Kathryn Duesman, BSN, RN

Despite decades of progress in healthcare, sharps injuries remain a persistent and alarming issue. Healthcare workers (HCW) continue to face unnecessary risks of exposure to bloodborne pathogens, such as HIV and hepatitis, from needlestick injuries. Despite innovations in medical technology and stricter regulations, the rates of these injuries are not dropping at the pace they should.

Retractable Technologies, Inc. (RTI) is acutely aware of this challenge. Our story began with a mission: to protect HCW who dedicate their lives to the care and well-being of others. We were founded not as a typical profit-driven venture, but as an organization rooted in advocacy for workplace safety, and that ethos remains the core of our purpose today. The HIV/AIDS crisis during the 1980s illustrated the importance of using truly effective safety technology to avoid creating additional needlestick injuries. Unsafe syringes cause collateral damage, putting HCW at risk, harming patients, and ultimately increasing disease. RTl’s safety syringe technology played a significant role in the President’s Emergency Plan for AIDS Relief (PEPFAR) initiative to reduce HIV transmission in developing countries. In addition, RTI has been a major supplier of safety syringes for the U.S. H1 N1 and COVID-19 pandemic response.

The Stubborn Reality of Sharps Injuries

Injuries Healthcare facilities worldwide have implemented a variety of safety measures, from training programs to safer devices, yet the rate of sharps injuries remains concerningly high. The Needlestick Safety and Prevention Act (NSPA), passed in 2000, was a landmark law aimed at reducing sharps injuries by requiring safety-engineered devices, along with improved recordkeeping of injuries. RTI was actively involved in advocating for this legislation, recognizing that the safety of HCW was being neglected. While the NSPA was a step in the right direction, its full potential has not been realized.

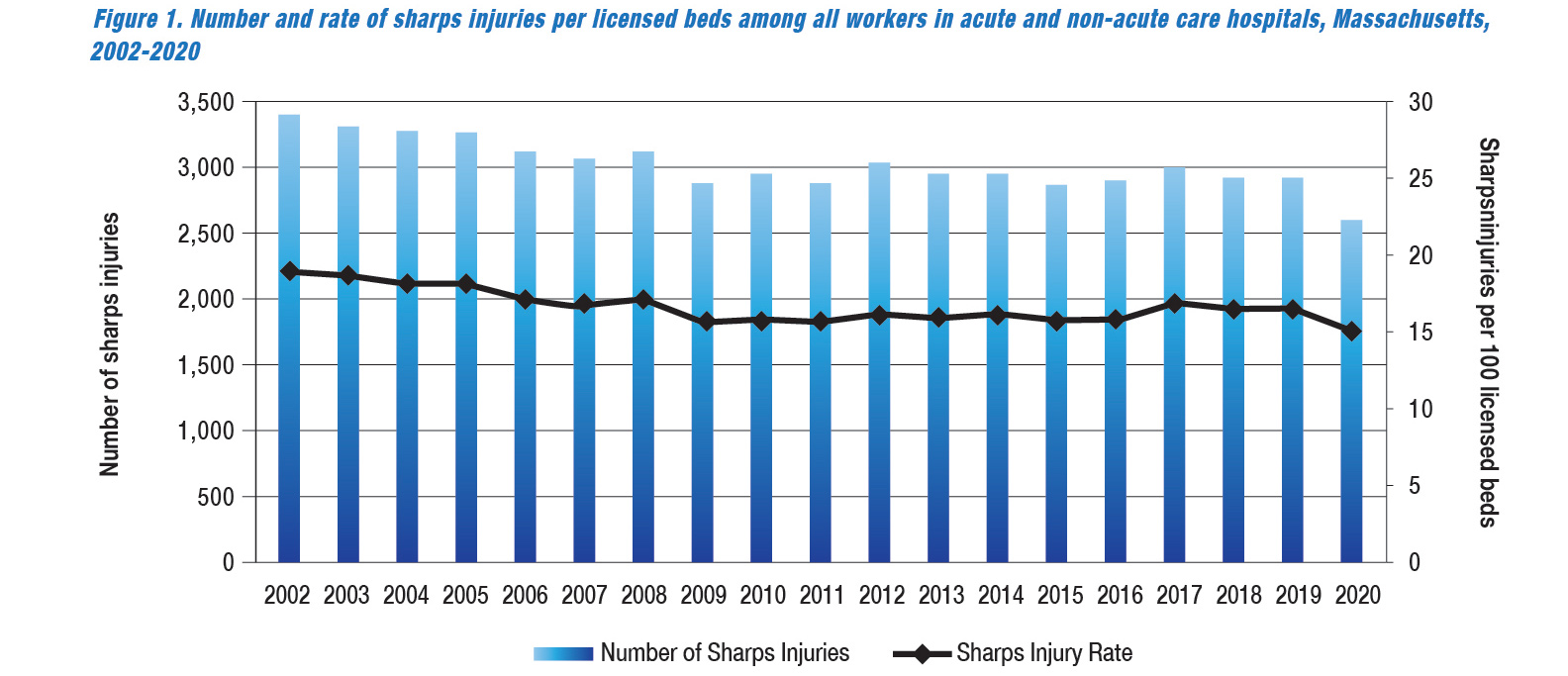

The Massachusetts Sharps Injury Surveillance System, 2020, showed that “the average annual percent change from 2009 to 2020 was 0.21 (p=0.38), indicating the rate remained relatively steady over that time period.” The following chart (Figure 1) was taken directly from the report. https://www.mass.gov/lists/needlesticks-sharps-injuries-among-massachusetts-hospital-workers “Data Brief: Sharps Injuries among Hospital Workers in Massachusetts: Findings from the Massachusetts Sharps Injury Surveillance System, 2020”

The graph illustrates that despite efforts to reduce needlestick injuries in Massachusetts from 2002 to 2020, the overall number of sharps injuries has remained relatively steady, hovering

between 2,500 to 3,000 injuries per year. While there is a slight downward trend in the sharps injury rate per 100 licensed beds, the reduction is minimal and does not reflect a significant improvement. This stagnation indicates that existing safety measures are not sufficient to protect HCW, reinforcing the need for enhanced safety protocols, updated technologies, and stricter enforcement to effectively reduce the risk of needlestick injuries in healthcare settings.

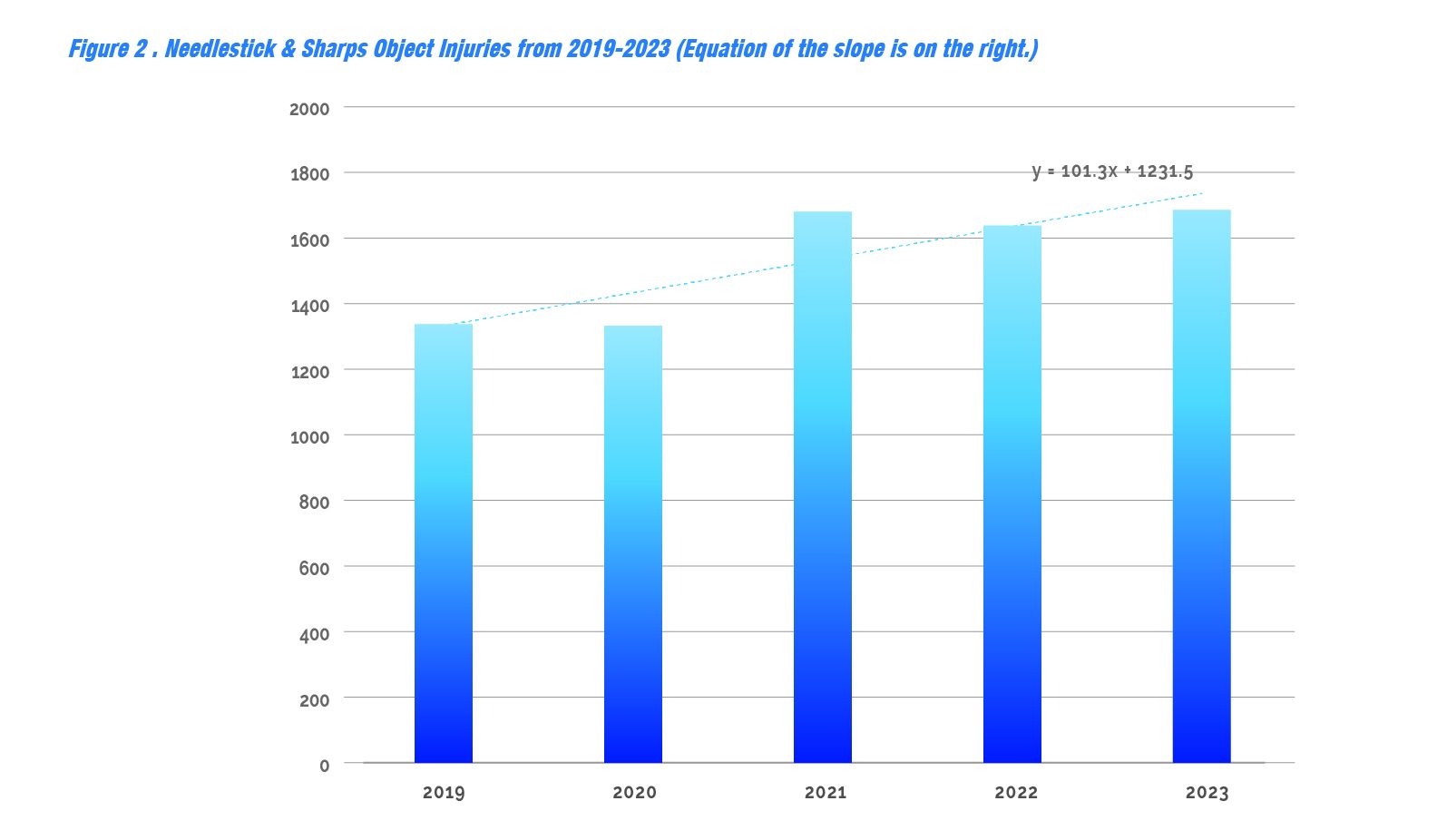

More recent data (Figure 2) from the International Safety Center (ISC) reveals that needlestick injuries have not decreased over the past five years. Through the ISC’s EPINet® system, which collects data from 40 U.S. healthcare facilities, it is evident that the number of needlestick injuries remains alarmingly consistent. This data, spanning the COVID-19 pandemic, suggests that HCW are still facing significant risks from sharp object injuries, and more effective strategies are needed to reduce these incidents. The steady trend highlights the urgency of improving workplace safety protocols to better protect healthcare professionals.

These statistics highlight a significant issue: while improvements have been made, they are not sufficient. Why is this still happening?

1. Limited Adoption of the Safest Devices: One of the most significant barriers to reducing sharps injuries is the lack of widespread implementation of the safest devices on the market. Despite the existence of advanced safety technologies, many healthcare facilities are restricted from adopting them due to contractual situations with certain manufacturers.

These contractual situations can often prioritize cost savings over worker safety, locking healthcare providers into contracts that prevent them from accessing the most effective, innovative solutions. This disconnect between available technology and its use in the field perpetuates the problem, leaving HCW at greater risk than necessary.

2. Underreporting of Injuries: The Centers for Disease Control and Prevention (CDC) estimates that in the U.S. about half of sharps-related injuries to HCW go unreported. Studies have shown the underreporting is more frequent among physicians and workers without needlestick injury training (Bahat et al., 2021). Contributing factors to underreporting also include a lack of understanding of the process and fear of retaliation or judgment. Underreporting can create a false sense of security, masking the true scale of the problem.

3. Inconsistent Safety Practices: Not all healthcare facilities maintain uniform safety standards. Whether due to budget constraints, staff shortages, or inadequate training, some institutions fall short in adopting and enforcing comprehensive safety measures. Occupational health professionals (OHPs) can advocate for safer devices by presenting injury data to demonstrate the financial and safety benefits of adopting improved equipment. By quantifying sharp injury logs and showing potential reductions in costs associated with workers’ compensation claims, lost productivity, and liability, OHPs can build a strong return-on-investment (ROI) argument for safer devices. Additionally, emphasizing compliance

with OSHA regulations and the liability risks of failing to provide safe devices can be persuasive for facility administrators and purchasing departments.

RTl’s Commitment to Workplace Safety

At RTI, our work is built on addressing the critical issue of sharps injuries. It started when RTl’s founder, Thomas J. Shaw, recognized the disconnect between the engineers designing medical devices and the frontline workers using them. From that moment, RTI was dedicated to designing medical devices with HCW safety in mind. Our story is a testament to the power of innovation and advocacy working hand in hand.

While we have developed products that are now used worldwide, including in Haiti and six African nations, our focus has always been on the broader goal of fostering safer workplaces for healthcare professionals. This commitment extends beyond creating safety engineered devices; it is about driving a

systemic shift in the healthcare industry. Workplace safety is not just about the devices used; it is about creating an environment where reporting injuries is encouraged, safety standards are maintained, and ongoing education about the dangers of sharps injuries is a priority.

The Need for a Cultural Shift in Healthcare

Reducing sharps injuries requires more than technical solutions. A cultural shift is needed within healthcare institutions, where safety becomes a valued part of everyday practice, not just a compliance requirement. This involves:

1. Promoting Transparent Reporting: HCW must feel empowered to report injuries without fear of punishment. Facilities should foster a culture that views reporting as a critical component of improving safety, not a reflection of failure. This includes reporting near-miss situations.

2. Strengthening Training and Awareness: Continual education is vital. Workers should receive regular training on safe practices for handling sharps and be made aware of the latest data on injury risks. Effective training on safe sharps handling should begin with comprehensive education upon hire, where HCW are introduced to safe practices and learn how to use devices. Vendors, including RTI, can provide hands-on demonstrations, showing staff the unique safety features of their devices and ensuring new hires are confident in their usage from day one. Additionally, following any sharps injury, prompt retraining of the device can reinforce safe handling procedures and prevent future incidents.

3. Engaging in Policy Advocacy: The fight for safer working conditions does not stop at the hospital doors. At RTI, we continue to push for better regulations that protect healthcare workers. This includes advocating on Capitol Hill, working with OSHA, and raising awareness among legislative staff about the urgent need for action. RTI has a longstanding commitment to advocating for HCW safety, a mission that began well before the passage of the Needlestick Safety and Prevention Act (NSPA) in 2000. This early advocacy helped shape the NSPA, which mandated the use of safer devices in healthcare settings. Since then, RTI has continued its efforts, working closely with organizations like OSHA to promote additional policies and improve enforcement mechanisms that protect HCW from needlestick injuries. Here is a link to join in on our support for workplace safety in hospitals; https://www.retractable.com/voice-your-support/

References

Massachusetts Department of Public Health. (n.d.). Needlesticks & sharps injuries among Massachusetts hospital workers. Commonwealth of Massachusetts. Retrieved November 20, 2024, from https://www.mass.gov/lists/needlesticks-sharps-injuries-among-massachusetts-hospital-workers

Bahat, H., Hasidov-Gafni, A., Youngster, I., Goldman, M., & Levtzion-Korach, 0. (2021). The prevalence and underreporting of needlestick injuries among hospital workers: a cross-sectional study. International journal for quality in health care : journal of the International Society for Quality in Health Care, 33(1 ), mzab009. https://doi.org/10.1093/intqhc/mzab009